Industry Dedicated to Dehydrted Beef Meat

CAYCE, S.C. -- In a constant search of ways to improve military rations, the U.S. Army Natick Soldier Research, Development and Engineering Center, Department of Defense Combat Feeding Directorate is now partnering with a commercial industry partner here to develop a meat product that uses an innovative dehydrating process.

The meat is ground, then dehydrated, or cured, in a continuous osmotic dehydration process that is less expensive than producing beef jerky and has more health benefits, too.

Tom Yang, a senior food scientist on the Food Processing, Engineering and Technology team at the Combat Feeding Directorate, said the meat "tastes very good and will be available in a variety of flavors."

The meat product costs about one-third of a similar jerky-type product, an important consideration in an era of dwindling dollars. It also has an estimated two- to three-year shelf life at ambient temperatures.

A FRENCH CONNECTION

The Association Pour Le Development De L'Institut De La Viande, a French Technical Center for Meat, in Clermont-Ferrand, France, originally developed the continuous osmotic dehydration process. By investing in the equipment and developing the product, the DoD is delivering a new process -- and new products -- to American industry.

"About three years ago I went to the International Institute of Food Technologists Exhibition," Yang said. "A French company was marketing osmotic dehydration as a continuous process. This process is very novel, and I think, 'This has potential for application to military rations.'

"The First Strike Ration is designed for the first 72 hours of deployment -- so called 'eat on the move' ration. I think a product made from this new technology can be a very good fit," Yang said.

"Commercial beef jerky tastes good, but it's very salty. And storing it at ambient temperatures for two or three years, it becomes dry and brittle," he said. The osmotically dried meat is more tender and moist, and could not only provide an alternative to traditional beef jerky but could also be used in a variety of other shelf stable ration components, such as sandwiches.

For funding, Yang submitted a proposal to the Foreign Comparative Testing Program managed by the U.S. Army Research, Development and Engineering Command's International Technology Integration Team for the Office of the Secretary of Defense, Comparative Testing Office.

"I was told this is the first time FCT has funded a project that wasn't related to weaponry or combat systems. Mine was the first one related to food. FCT was happy to fund this novel technology," Yang said.

PARTNERING WITH INDUSTRY

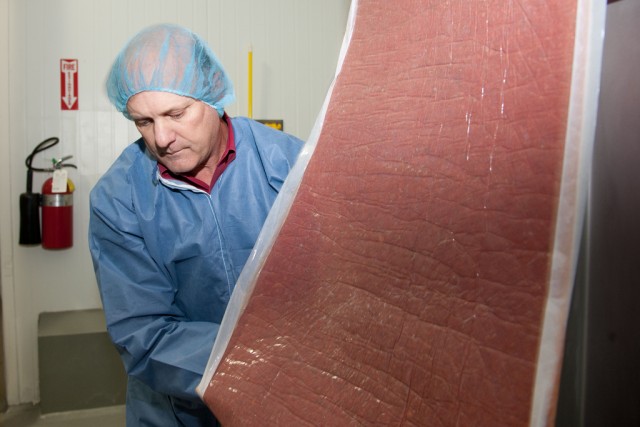

The Combat Feeding Directorate is partnering with FPL Foods, headquartered in Augusta, Ga., the largest integrated food processing company in the Southeast. The continuous osmotic dehydration processor was installed in May 2012 in FPL Food's Cayce plant.

Combat Feeding and FPL Foods are now developing an array of products with the new technology and recently drafted a cooperative research and development agreement to outline their efforts.

FPL Foods revamped an area in the Cayce plant to house the equipment and is supplying manpower to develop the products. Combat Feeding supplied the FCT funds to invest in the equipment.

"To our knowledge this is the only system like this in the United States," said Randal P. Garrett, chief operating officer for FPL Foods.

"For us to be competitive we have to be on the leading edge," he added. "We're in tune with what the DoD is trying to develop.

"We've done our initial development -- six runs so far -- and consumer marketing is coming, once we have a variety to show," he added.

Yang estimates the product will be ready for military test and evaluation in about 8 months.

"It's a very simple concept," Yang said of the process. "You take lean meat, and grind it up. This can be beef, poultry, pork, or even seafood, fish, or a combination, even fruit or vegetables."

Flavor and nutrients are added when the meat is being ground before it enters the dehydration process.

"The meat is extruded into a thin sheet on a sheet of parchment paper on a conveyor system. It is then pulled through an osmotic solution [composed of sucrose/sodium chloride/water] that extracts moisture," Yang said.

The finished product resembles a Fruit Roll-up, a candy item developed in 1983.

Garrett said the meat product has a quality that may redefine the jerky/meat stick market.

"Our initial thought was, 'Well, let's see if we can make a different jerky product,'" he said, explaining how FPL Food's vision has expanded. "Let's now try to produce something that's in great abundance. Let's look at fortified meat products for campers, hikers, those who are health conscious. There's also interest from folks looking for pepperoni and salad toppings.

"Grill or bake, the way we look at it, the only thing it wouldn't replace is a steak. That has unique properties," Garrett added.

"We have customers in the deli business who want to put it on their sandwiches, and restaurants for their salad bars," he continued. "It lends itself to salad bars, with its long shelf life, and it's safe for consumers.

"It's healthy and nutritious and we can make it out of almost anything. We can use any type of meat and blend it together, [even] high Omega 3 products," Garrett said.

"We look at this as an opportunity to develop some meat products that people will like," he said.

"The osmotic process doesn't require a lot of input energy," Garrett added. "We're using a room-temperature solution to dry the product that doesn't require excessive energy, and we can reconstitute the solution and use it again.

"We're looking to fit into our green space, to be better corporate citizens to our community, and being as friendly to the environment as we can," he added.

MANY MILITARY USES

Yang envisions many military uses for the meat product.

"Warfighters like something that is meaty, tasty and healthy -- a high energy product," he said. "This will make a lot of product. It's very juicy, with whatever nutrient you want in there, and it will be well preserved."

"There's no heat involved, other than two minutes of pasteurization at 160 degrees Fahrenheit to remove bacteria and make it shelf stable. If it lasts three years, it will be a good fit for Meals Ready to Eat or First Strike Ration," Yang added.

The Combat Feeding Directorate ration teams are pleased with the product and its many potential applications to expand ration menus, according to Yang.

"The ration teams have evaluated it, as well as the Warfighters, technical sensory evaluation panels, dieticians, nutritionists, and food scientists like myself. They gave it a critical evaluation and it ranked very high," he said.

"The only challenge is they want more spice. They want a stronger flavor, like Tabasco sauce, teriyaki flavor, barbecue -- and this is very easy to do with this process," Yang said.

"We came up with salami flavor; it's very good. You can eat as it is or use it as a pizza topping. There is a chipotle flavor, too. A similar product made from turkey, called turkey jerky, was good. Pork and smoked ham enhance the flavor and that turned out very well."

Another product made from fish also impressed the dietitians.

"Of course, the recipe needs to be tweaked to make it less fishy," Yang added.

Related Links:

U.S. Army

Army Materiel Command

U.S. Army Research, Development and Engineering Command

FPL Food

Source: https://www.army.mil/article/87419/wheres_the_beef_dod_finds_answers_in_osmotic_dehydration_process

Belum ada Komentar untuk "Industry Dedicated to Dehydrted Beef Meat"

Posting Komentar